Quality is the figurehead for the success of Müller Plastik. Because only those who convince with high-quality products, advice and service can satisfy their customers in the long run. By using our products in your application, you are dependent on our quality. And we assure you of this!

The high quality standard at Müller Plastik is ensured by the most modern test facilities and test processes as well as by the well-trained and experienced staff. For the electrical and automotive industry, the results from developed and tested quality "made by Müller Plastik" are the highest possible reliability on the products with appropriate documentation, e.g. IMDS / PPAP / VDA PPF. Of course, our products meet all current norms and standards.

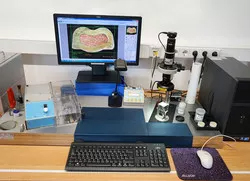

microsection laboratory

alternating bending tester

tension compression tester

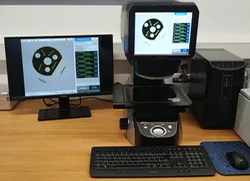

measuring projector

In all work processes, we strive for continuous improvement and consider quality as an integral part of all activities. We benefit from our many years of experience and excellent industry knowledge. Müller Plastik GmbH is certified according to ISO 9001: 2008. This is the nationally and internationally most widespread and most important standard in quality management, which is based on seven principles:

Meeting the needs of customers

Mediates and communicate strategies and processes of the company

Also, by recognition, capability and promotion of skills

Processes as a part of the system to increase performance

To ensure competitiveness and identify new opportunities

On the basis of data or evaluations

To customers, suppliers and internal

ISO certification serves, among other things, the transparency of operational procedures, a low error rate and cost reduction. With this regularly audited ISO 9001: 2008 certification from TÜV Rheinland, we want to prove our high quality standards that you can rely on.

The so-called control loop of quality management is not only lived but also internalized. This consists essentially of four steps:

Quality planning: After determining the current status through internal or customer audits, we have defined the framework conditions for quality management and created concepts and procedures.

Subsequently, the quality information regarding cost-benefit considerations is analyzed within the quality assurance process and the assumptions made previously are evaluated.

In the course of quality control, the results of quality planning and sampling are implemented and the corresponding know-how recorded in the Failure Mode and Effects Analysis (FMEA).

This is followed by structural improvement measures and optimization measures for gaining quality, including communication of success and results.

Quality management, as used by Müller Plastik, serves to optimize products and processes, which not least increases customer satisfaction. Your safety is always the focus, but fair prices and fast delivery are just as important to us as personal contact and short response times.